KBH Grinding and Calibration System

Precise Calibration and Grinding up to 1200 mm (48“) width

Quick Facts

-

Processing width: 600 – 1200 mm (24“ to 48”)

Versatility: Suitable for concrete slabs, paving blocks, lightweight and heavy weight concrete elements

Sensor system: Integrated sensors for precise control of grinding intensity

Optional Upgrade: Quick tool change system for ease of tool change

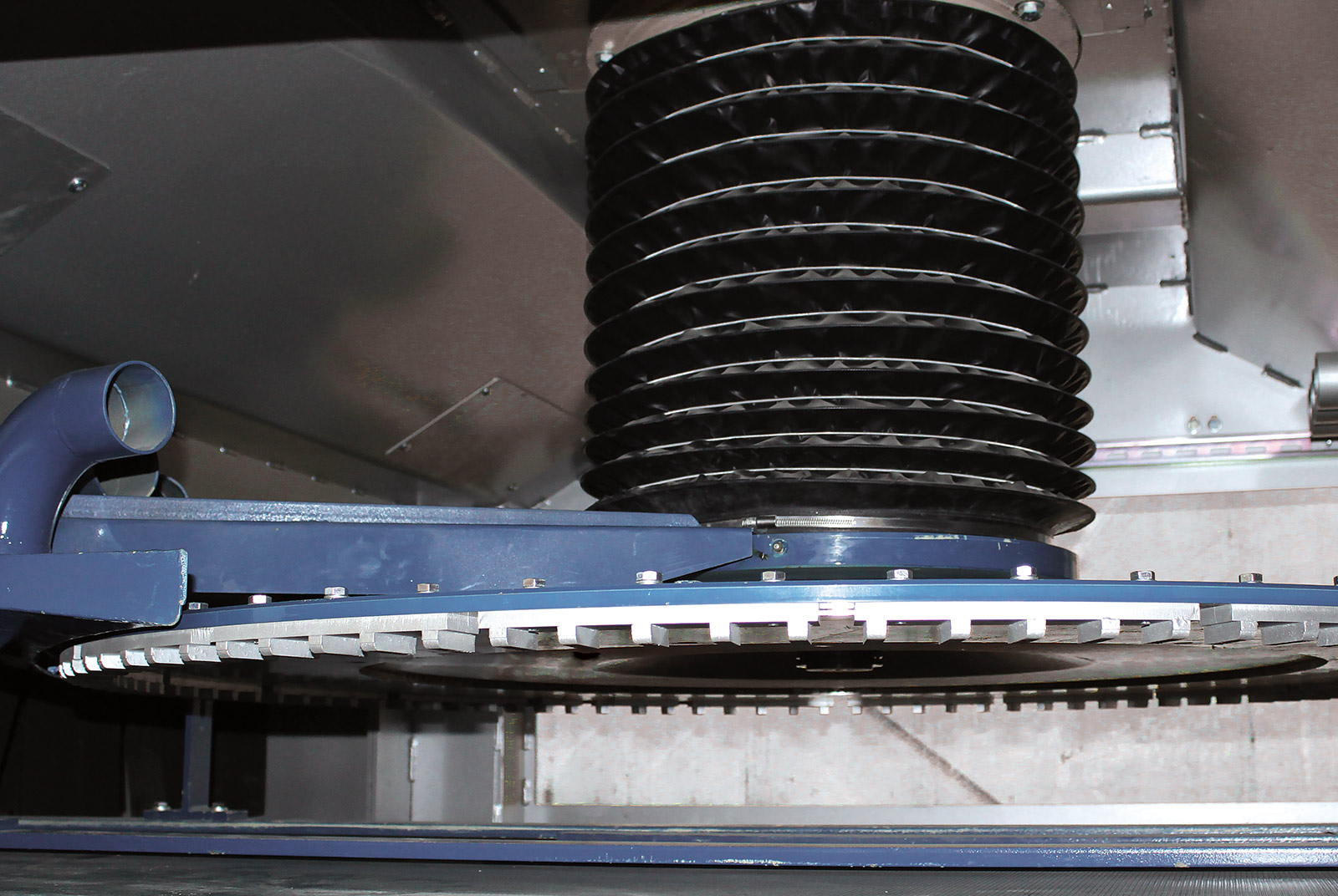

Working Principle

Grinding creates special surface finishes. The process begins with product back calibration to eliminate deviation of product height. After calibration, the stone layer is rotated backwards to bring up the face side for treatment. A very thin layer is removed in this step to slightly grind or expose the surface aggregate. The system uses precisely guided grinding tools. Special sensors allow for very sensitive tool adjust – for each grinding head. This ensures consistent and repeatable grinding results – regardless of product format or material density. The optional tool quick-change system minimizes setup times and maximizes machine availability.

Why Choose KBH Grinding and Calibration System

- Precision meets flexibility: Sensor-controlled grinding ensures a perfect finish at all times.

- Ready for any challenge: Whether light or heavy weight concrete elements – our system adapts to your product range, with processing widths of up to 1200 mm (48”)

- Time-saving & efficient: The tool quick-change system boosts your productivity significantly.

- Integration with multi-finishing lines: Seamless connection with other KBH finishing technologies possible.

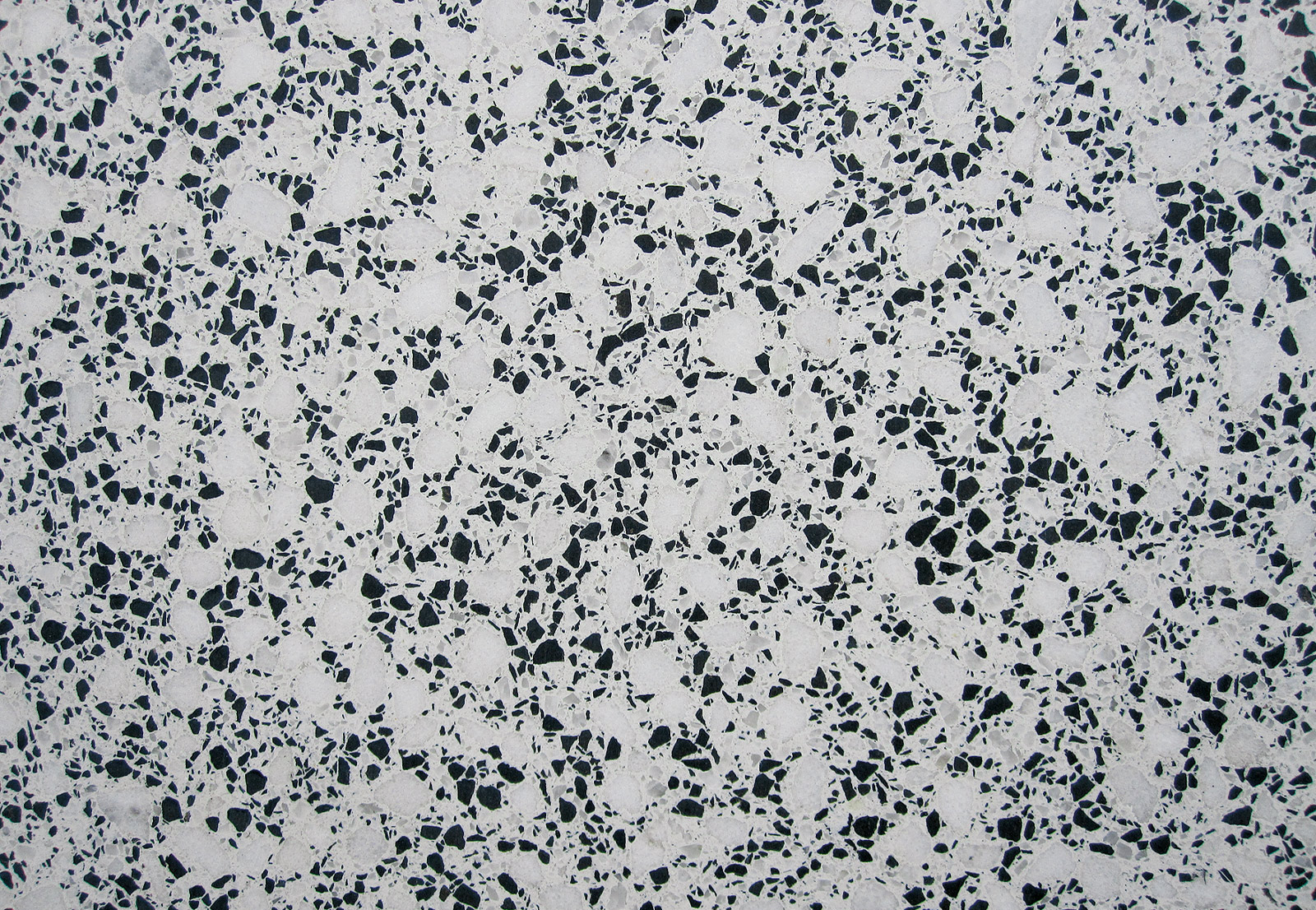

Samples

Downloads

Questions about the product

Do you have questions about our products?

Our product managers will be happy to answer all your questions at

+49 (0) 8331 - 9503-15