KBH Crusher

Efficient Recycling and Reintroduction of Concrete Waste

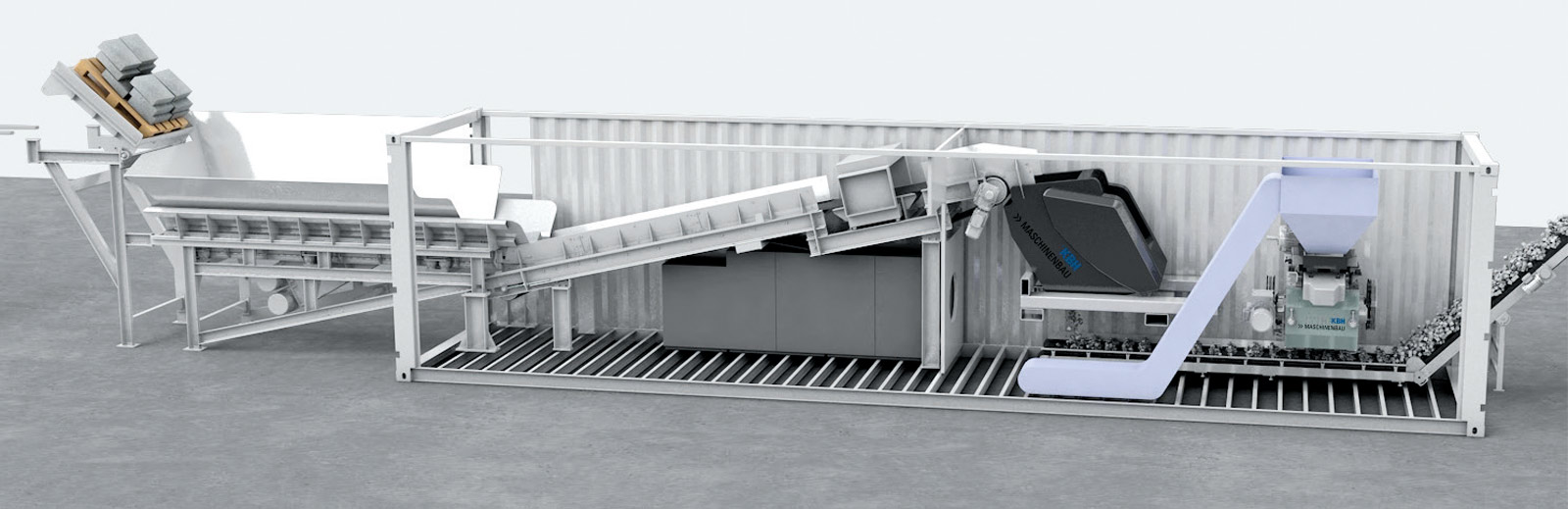

The KBH CRUSHER offers an innovative solution for recycling concrete waste directly from the quality control station, eliminating the need for intermediate storage. This compact containerized system allows for the direct reintroduction of recycled material back into the manufacturing process, enhancing both efficiency and sustainability. With multiple feeding options and a flexible configuration, the KBH CRUSHER can handle a wide range of materials, from slabs and pavers to curb stones and step stones. The system operates with no additional labor requirements and is designed to deliver high output while maintaining low operational costs.

Quick Facts

- Recycling Process: Direct recycling from the quality control station without intermediate storage

- Integration: Seamless reintroduction of crushed material into the manufacturing process

- Design: Compact container solution with separate compartments for feeding and crushing

- Material Handling: Accommodates various feeding methods, including forklift trucks and shovel loaders

- Flexibility: Available in single or dual crusher configurations for customizable grain size output

- Efficiency: Operates with low energy consumption and wear costs

Working Principle

The KBH CRUSHER uses a specialized jaw crusher to process concrete waste directly from the quality control station, avoiding the need for intermediate storage. The machine can be configured in a single or dual crusher setup to accommodate varying grain size requirements, from 0-13 mm to as fine as 0-4 mm. The crushed material is then immediately available to be reused in the paver production. The system can process all kinds of stones from small sizes up to curb stones or step stones It is compact and containerized, with a dust suppression system or an optional dust extraction system to maintain a clean working environment. With its flexible feeding options, including tilt tables and vibratory chutes, the KBH CRUSHER ensures continuous operation and high throughput, all while keeping energy and wear costs low.

Why Choose KBH CRUSHER

- Direct Recycling: Streamlines the recycling process by eliminating intermediate storage, reducing waste management complexity.

- Compact Design: Containerized solution that fits easily into existing plant configurations.

- Versatility: Can process a wide range of materials with adjustable grain size output for various applications.

- Cost-Efficiency: Low energy and wear costs ensure sustainable operation.

- Minimal Labor: Designed for automated operation, reducing the need for additional labor.

Downloads

Questions about the product

Do you have questions about our products?

Our team will be happy to answer all your questions at

+49 (0) 8331 - 9503-15