KBH Printing System Wetside

Simplifying and Enhancing Concrete Printing

The KBH PRINTING SYSTEM WET SIDE offers a groundbreaking approach to concrete printing, moving the process to the wet side of production. Unlike traditional methods that print on the dry side and require multiple surface treatments, the KBH system streamlines production by integrating printing and cement paste neutralization directly on the wet side. This innovative method enhances flexibility, reduces costs, and improves process reliability. Utilizing UV-resistant inorganic ink specifically designed for wet side application, this system allows for deeper ink penetration and superior finish quality. The KBH PRINTING SYSTEM is adaptable for both new installations and retrofits, offering significant savings and advanced technology for modern concrete production.

Quick Facts

- Innovation: Prints directly on the wet side, eliminating the need for multiple surface treatments

- Compatibility: Suitable for integration into existing plant configurations and greenfield sites

- Technology: Uses state-of-the-art printers with UV-resistant inorganic ink for deeper penetration and durability

- Process Efficiency: Simplifies production with a single coating application on the dry side

- Cost-Effective: Reduces operational costs by minimizing the need for additional drying solutions

Working Principle

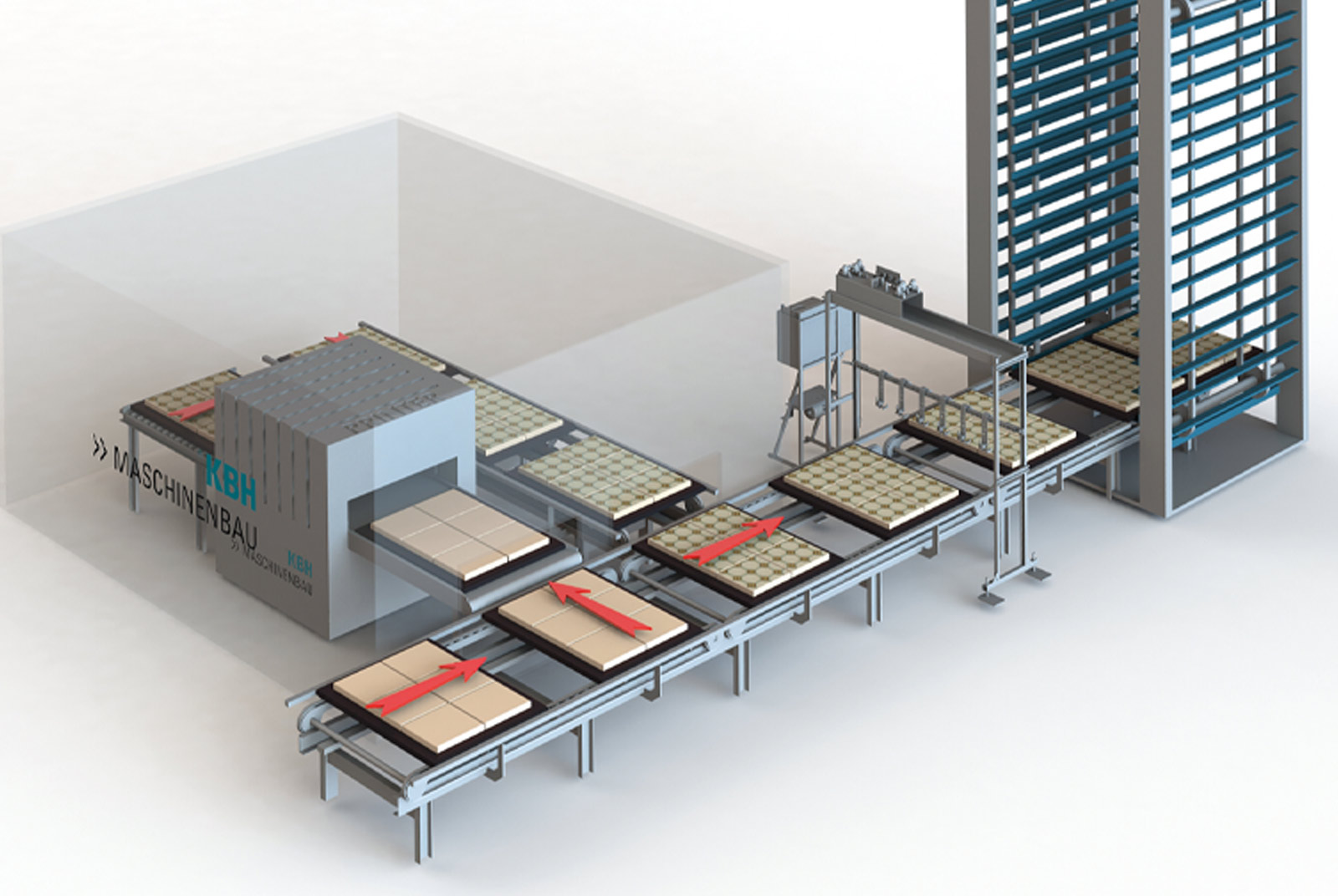

The KBH PRINTING SYSTEM WET SIDE optimizes the concrete printing process by shifting it to the wet side. Products are produced using a paver machine, and printing is performed immediately after the cement paste is neutralized. The use of UV-resistant inorganic ink allows for deeper penetration into the concrete surface, resulting in a high-quality finish. The printed products then undergo regular curing in a drying chamber, followed by a single surface protection coating on the dry side. This streamlined process reduces complexity, enhances flexibility in product design, and lowers costs.

Why Choose KBH PRINTING SYSTEM WET SIDE

- Simplified Production: Moves printing to the wet side, eliminating the need for complex surface treatments and reducing production steps.

- Enhanced Quality: Deeper ink penetration and high-quality finish due to UV-resistant inorganic ink specifically developed for wet side applications.

- Cost Savings: Significantly reduces costs associated with drying and surface treatments, offering a more economical solution.

- Flexible Integration: Suitable for new installations and retrofits, allowing easy integration into existing production lines.

- Innovative Technology: Incorporates advanced printing technology, ensuring a cutting-edge solution for concrete printing.

Samples

Downloads

Questions about the product

Do you have questions about our products?

Our product managers will be happy to answer all your questions at

+49 (0) 8331 - 9503-15